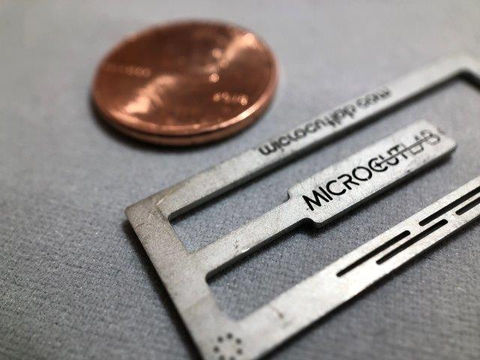

Microcut Lab

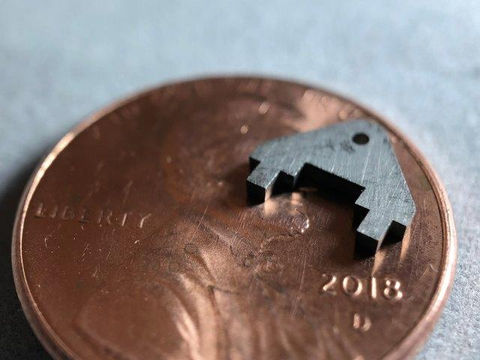

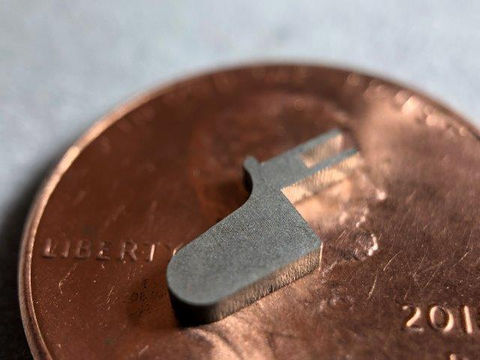

Nitinol, polyimide and stainless steel laser cut components

Why Microcut Lab?

Microcut Lab’s design and engineering team are experts in robotics, precision mechanisms, and medical devices, offering quick quotes and part delivery.

Capabilities

Microcut Lab was founded to help design engineers in the medical device industry. Microcut Lab are specialists in laser cutting, laser welding, and Nitinol processing with heat setting and electropolishing. Quick turn parts in a few days... not weeks!

Microcut Lab's offerings include:

Specialized materials including Nitinol

Extremely tight tolerances (+/- 00005”)

Small features with interior radii as small as 0.001"

Small hole drilling in tubes

Flat sheet

Cut Tubes to length

Eliminate aspect ratio constraints of photo-etching

Combine multiple laser cut parts into complex geometric assemblies

Heat setting and electropolishing

Size Requirements:

Single part up to 12" x 12"

Part thickness of up to .125" for stainless, .050" for polyimide, and .063" for aluminum

Nitinol

Polyimide

Stainless Steel

Titanium

Tantalum

Brass

Copper

.png)