Precision Laser Cutting

What is Precision Laser Cutting?

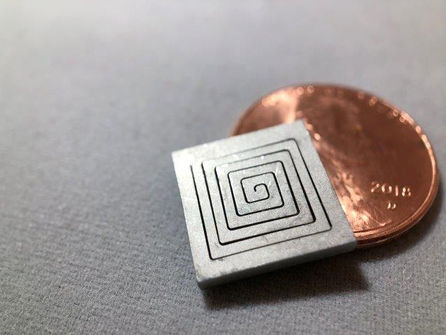

Precision laser cutting is a fabrication process that uses a laser to vaporize metal sheet or tubing, resulting in a cut edge. Laser cutting works by directing the output of a high-powered laser, most commonly through optics. The laser optics and numerical controls (CNC) are used to direct the laser beam to the material.

Precision cutting lasers use motion control systems to follow a CNC pattern to be cut onto each chosen material. The focused laser beam is directed at the material, which then either melts, burns, vaporizes away, or is blown away by a jet of gas — leaving a cut edge with high-quality surface finish.

How Does Precision Laser Cutting Work?

In precision laser cutting, a laser beam is focused on the work zone using a high-quality lens. The quality of the beam has a direct impact on the focused spot size. The narrowest part of the focused beam is generally less than 0.0125 inches in diameter. In order to start cutting a location other than the edge, a pierce is done before every cut. Piercing usually involves a high-power pulsed laser beam which slowly makes a hole in the material.

Parallel rays of coherent light from the laser source often fall in the range between 0.06–0.08 inches in diameter. This beam is focused by a lens or mirror to a precise spot of ~0.001 inches with concentrated intensity.

Precision laser cutting is primarily done on four types of lasers:

CO2 laser - Suitable for cutting, boring, and engraving.

Neodymium (Nd) laser - Used for boring in high-energy, low-repetition applications.

Neodymium Yttrium-Aluminum-Garnet (Nd:YAG) laser - Identical in style to a Nd laser, but instead used for very high-power boring and engraving.

Fiber laser - Ideal for cutting reflective metal. Extremely small spot size, up to 100 times smaller than a CO2 laser.

Advantages of Fiber Laser Cutting

Fiber lasers are a type of solid state laser that is rapidly growing within the metal cutting industry. Fiber technology uses a glass fiber to amplify the beam generated by the "seed laser". With a wavelength of only 1064 nanometers, fiber lasers produce an extremely small spot size — up to 100 times smaller than a CO2 laser. Along with this benefit, fiber lasers offer several other advantages, such as:

Rapid processing times

Reduced energy consumption due to greater efficiency

Greater reliability and performance - No optics to adjust or align and no lamps to replace

Minimal maintenance

Ability to process highly reflective materials, such as copper and brass

Higher productivity and lower operational costs

Advantages of Precision Laser Cutting

Precision laser cutting offers many advantages, such as:

Wide material selection including specialized metals and plastics

Extremely precise tolerances as tight as ± 0.0005 inches

Fine features including interior radii as small as 0.001 inches

Ability to process sheet or tube material

Removes aspect ratio constraints of photo-etching

Low risk of material warp due to laser's small heat-affected zone

Precision Laser Cutting Materials

A wide range of sheet and tube material can be precision laser cut, including:

Stainless Steels

Mild Steels

Aluminum

Copper

Nitinol

Titanium

Tantalum

Brass

High-performance plastics such as Polyimide

Precision Laser Cutting Applications

Precision laser cutting is used in a wide range of industries and products. Some examples include:

Aerospace: Components used in key functional areas of aerospace equipment including engine parts, exhaust, filtration and control systems

Industrial: Flow and moisture sensors, agricultural equipment, commercial door hardware, packaging equipment, heating plates

Medical: Stents, orthopedic fixtures (screws / plates / anchors), stimulators (neuro / spinal / cardio), catheters, blood analyzer brackets, cart storage trays, sterilization instruments, device chassis

Technology: Communications weldments, ATM chassis, lottery machine enclosures, audio housings, spring plates

Transportation: Brake discs, pedal guards, seat heater components, fitness controls, license plate brackets, mirror holders, polished heel guards

.png)