Box Build

What is Box Build?

Box build, or system integration, ranges from packaging printed circuit board assemblies (PCBAs) into an enclosure to full electromechanical product assembly. Box build often spans the full product lifecycle — including design, prototyping, production, and final assembly.

Many Original Equipment Manufacturers (OEMs) leverage outsourced high-level box build for two reasons:

Limit in-house assembly costs and labor requirements

Receive delivery of a "plug and play" sub-assembly or complete product to optimize specialization

How Does Box Build Work?

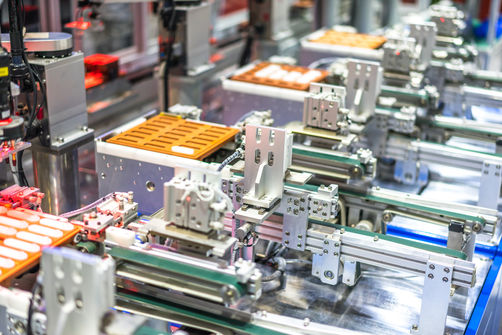

Box build refers to a combination of electronic assembly and mechanical pack-out. Box build engagements often start with a single technology — most commonly, printed circuit board assembly — that is controlled directly by the contract manufacturer. A PCBA project might evolve into a box build through the addition of electrical and mechanical assembly work.

Electronic contract manufacturers participate in many aspects of box build production for OEM customers, such as:

Product development

Prototyping

Manufacturing

Software and firmware programming

Testing

Packaging

Labeling

Warehousing

Distribution

Return and repair services

The OEM typically maintains ownership of all box build specifications, requirements, bill of materials (BOM), and tooling.

Advantages of Box Build

Box build, or systems integration, offers many advantages:

Complete customization to specified requirements

"Plug and play" incorporation with the final product

Lower total cost of ownership

Higher level of quality and performance assurance

Maintain full control over design and BOM

Optimized division of responsibilities between OEM and contract manufacturer

Direct control of high-value BOM items

Test, validation, and regulatory approval readiness

Box Build Materials

A wide range of components and materials can be assembled into a box build. For example:

Printed circuit board assemblies

Metal or plastic enclosures and structurals

Cable assemblies or wire harnesses

Battery packs

User interface controls

Motors

Pneumatic systems

Box Build Applications

Box builds are used in a wide range of industries and products. Some examples include:

Aerospace: Radars, beacons, avionics, aircraft on-board equipment, airport security equipment, flight simulators and instrumentation, satellite test equipment

Consumer: Smartphones, computers, TVs, appliances, kiosks / self service

Defense: Missile-related devices, power distribution, fixed or mobile ground communications, tactical communications, control and security systems

Energy: Smart usage monitors and controls, clean energy instruments, power management

Medical: Surgical and dental handpieces, wheelchairs and scooters, breast pumps, dialysis machines, ambulatory and fixed infusion pumps, cosmetic and surgical lasers, radiation therapy and linear accelerators

Technology: Communications, servers, power and utilities equipment, sensors, AI/information technology, scientific instrumentation, connected devices

Transportation: Cars, autonomous robotics, drones

.png)