Seaway Plastics

Low to medium volume plastic injection molding production parts from fully engineered in-house rapid cut tooling in 2-5 weeks

Certifications:

ISO 9001 | ISO 13485 | FDA Registered | ITAR

Locations:

Port Richey, FL | Brooksville, FL | Santa Rosa, CA | St. Paul, MN

Why Seaway Plastics?

Seaway Plastics offers complete in-house custom plastic injection molding and tooling services − tool design, tool building, and molded parts − from its bi-coastal U.S. manufacturing facilities.

Capabilities

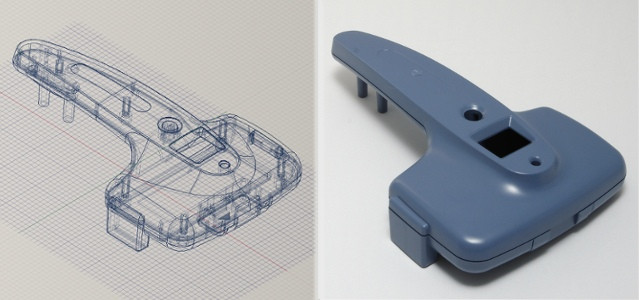

Seaway Plastics specializes in designing and building aluminum and steel tooling for plastic injection molding and custom molded parts from almost any engineered resin. With Seaway, your tool is produced directly from your model via file-to-cutter manufacturing. Seaway’s engineering team collaborates with you for DFM, prototyping, material selection, and injection molding tooling options.

Low volume injection molding refers to creating a “low” number of parts using the injection molding services and where that number begins depends on the manufacturer. Seaway-classifies batches ranging between 100 and 10,000 pieces as “low volume”. Their average production lot is 1,000 pieces and progresses upwards from there.

Seaway has ISO Class 7 cleanroom plastic molding in Florida and ISO Class 8 cleanroom plastic molding in California. Both classes define the need to control the particulates and contaminants that can enter the room before, during, and after molding. Seaway’s Class 7 cleanrooms are climate controlled with special HEPA filters that remove airborne particles as small as 0.3 microns, and their Class 8 cleanrooms have filters that remove particles as small as 0.5 microns. Both facilities meet the ISO 13485 certification standards required to manufacture most medical devices. Seaway’s cleanroom environments are also suitable for the production of electronics, pharmaceutical packaging, automotive parts, and more.

For parts that require multiple plastic materials, Seaway offers both two-shot injection molding and overmolding. Two-shot molding is best for higher volumes and injection molded parts that have complex geometric shapes and colors to create beautiful and seamless products. Overmolding usually suits low-volume or on-demand projects. Engineers often use overmolding because it is easier for design as they can fit in just about any standard injection molding machine for this process.

Liquid Silicone Rubber (LSR) molding is the process used to create robust, pliable, high-precision, high-quality parts in large numbers. Liquid Silicone injection molding produces parts that are highly water repellent and resistant. LSR parts are ideal for use as seals, membranes, electrical connectors, and a variety of other medical, commercial and domestic applications. The LSR process requires a large range of tooling knowledge and execution, unique equipment and mechanical components. Seaway’s MME Group has the capacity to provide LSR design, tooling, molding and full assembly services in one location.

Seaway’s value-added and secondary services include:

Product assembly

Ultrasonic cleaning

Sonic welding

Heat staking

Thermal and ultrasonic inserting

Post molding machining and CNC machining

Laser marking

Full painting capabilities

Screen printing and Pad printing

EMI/RFI shielding

Thermoplastic Resins such as Acetyl, Acrylic, Liquid crystal polymers, Nylon, Polycarbonate, Polyester, Polyethylene, and Polyurethane

Thermoplastic Elastomers such as soft rubber and urethane based materials - common for overmolding soft touch handheld components

Materials with additives such as glass fiber, nickel, and minerals for performance characteristics

Liquid Silicone Rubber (LSR) - an elastomeric material, common to the medical market

.png)